Analysis of the economic viability and environmental impacts of a conceptual process for the recovery of lactic acid from spent media in cultivated meat production

Analysis of the economic viability and environmental impacts of a conceptual process for the recovery of lactic acid from spent media in cultivated meat production

Wimble, J.; Ashizawa, R.; Swartz, E. W.

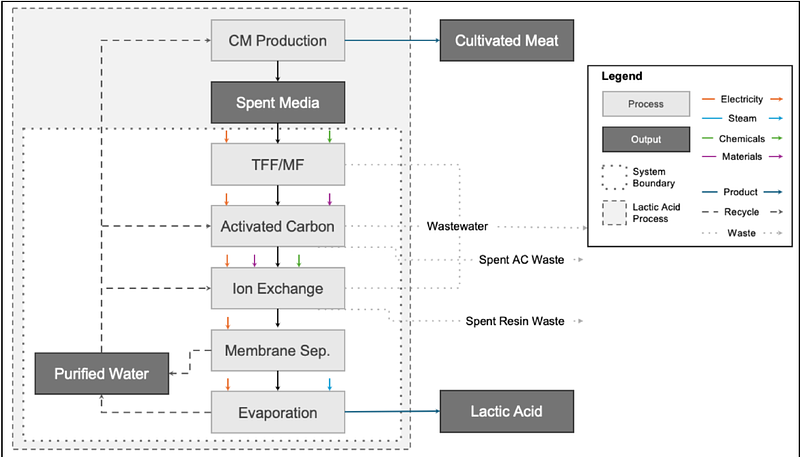

AbstractThe scaled production of cultivated meat implies a future where large amounts of liquid waste in the form of spent media will be co-produced. Recycling of spent media, specifically certain abundant metabolites such as lactic acid, offers an opportunity for valorization and to offset the carbon footprint of cultivated meat production, however, the feasibility of recovering lactic acid from spent media has yet to be examined in detail. In this study, we developed a conceptual design of a five-step lactic acid recovery process integrated into a previously modeled cultivated meat facility. We examined the corresponding cost and environmental impacts of recovering an 88% aqueous, polymer-grade lactic acid solution and compared these footprints to data from commercial lactic acid fermentation processes. At an anticipated lactic acid concentration in spent media of 3 g/L, we found that the net cost of recovery would be $0.71 per kg of 88% lactic acid, with a 7.5 year simple payback period. Sales of this co-product could offset $0.06/kg of the cost associated with the production of cultivated meat. Depending on allocation scenarios, the environmental impact of the recovery process had a -1.0 to +0.2 kg CO2 eq effect on the overall carbon footprint and a -22 to +3 MJ effect on cumulative energy demand per kg of cultivated meat production. These results suggest that the recovery of lactic acid may be an economically viable and environmentally beneficial practice if implemented in future production facilities. This study provides crucial guidance for lactic acid valorization and other media recycling strategies for cultivated meat that can be applied to broader animal cell biomanufacturing industries.